When it comes to choosing the right benchwork for your Model Railroad, be it big or small, it’s important to consider the quality, ease of assembly, and overall functionality of the product. In addition, overall price and standard features should also weigh in your decision.

In this competitor comparison, we will take a closer look at the four main manufacturers of Model Railroad Benchwork Kits: The Model Railroad Benchwork Store, Sievers Benchwork, Mianne Benchwork, and MRBenchwork.com to help you determine which manufacturer has the best overall options and affordability, as well as a brief overview of each one’s assembly and construction techniques.

Below is a handy quick-reference comparison table between all four manufacturers in key areas such as materials, customizations, size range, leg style, options, and price to help you make an informed decision on which manufacturer to use. Following that you will find a brief description of each manufacturer’s design highlights and our Top Pick. At the end of this article you will find a little background information about the authors experience in Model Railroading and carpentry.

| Manufacturer: | The Model Railroad Benchwork Store | Sievers | MRB | Mianne |

| Sizes | Unlimited | Pre-Defined | Pre-Defined | Pre-Defined |

| Customizable? | Yes | Yes | Yes | Yes |

| Added Cost? | No | Yes | No | Yes |

| Side Rail Material | 3/4″ Birch Plywood | 3/4″ Pine | 3/4″ Baltic Birch Plywood | Hardboard/Wood |

| Max Side Rail Length | 96 Inches | 48 Inches | 84 Inches | 48 Inches |

| Cross Piece Material | 3/4″ Pine/White Wood | 3/4″ Pine | 3/4″ Baltic Birch Plywood | Hardboard/Wood |

| Max O.C. Spacing | 16 Inches | 12 Inches | 16 Inches | Not Specified |

| Drilled for Wiring? | Yes- Standard | Yes-Standard | Yes-Standard | Not Specified |

| Joining Method | Butt Joint | Butt Joint | Butt Joint | Butt Joint |

| Fastener Style | Screws/End | Screws/End | Pocket Hole Joinery | Cam Bolts |

| Alignment Method | Pressure Blocks, Installed | None | Pencil Lines | Matching Cam Holes |

| Standard Leg Style | L-Girder with (2) Braces Each | Flat H Style | Flat H Style & L-Girder | Flat H Style |

| Pre-Assembled? | Yes | No | No | No |

| Levelers Standard? | Yes-Threaded Steel Inserts | Yes-T-Nuts | No | Yes-Type Not Specified |

| Installed? | Yes | No | No | Not Specified |

| Height Adjustment | 2 Inches | 1 Inch | 2.5 Inches | Not Specified |

| Leg Lengths | Customer Specified, 30-60 Inches | Pre-Defined Lengths Only | Pre-Defined Lengths, Cut Upon Request | Pre-Defined Lengths Only |

Lowest Price: The Model Railroad Benchwork Store

Don’t let their lowest price rating fool you, The Model Railroad Benchwork Store prides itself on offering Complete Starter Table Benchwork Kits and Modular Benchwork Kits that are designed for simplicity and efficiency. They offer standard features that are only available as cost upgrades from the others.

Their one-piece side rail design of up to 96” in length eliminates the need for additional support legs, saving you both time and money, and they are the only manufacturer that offers this. With standard features like pre-drilled holes for wiring, threaded steel insert leg levelers, L-Girder style legs with 2 diagonal braces each, ¾” birch plywood side rails, and their exclusive pressure block assembly method, it’s clear that The Model Railroad Benchwork Store has thought of everything to make your model railroad setup a breeze.

Additionally, their Model Railroad Benchwork Kits are available in a nearly infinite range of sizes due to their customer defined widths and lengths in a simple tiered pricing arrangement. It truly is custom benchwork at non-custom prices. Their Complete Table Kits can also be custom tailored to size using the same simple pricing plans.

Their Model Railroad Benchwork is comprised of ¾” plywood side rails and 1×3 white wood or 1×4 select pine cross pieces depending on the spans. Their standard legs are made up of 1×3 white wood, pre-assembled with levelers installed; a nice touch that the others don’t have. Their placement is also set in from the sides and ends to prevent accidental kicking, another bonus on their well thought out design.

Other optional adds include inside or outside diagonal corners, curved inside or outside pieces, drop sections, recessed foam top construction, precise cut-to-length risers to match your track plan and grade profile, and custom layout designs.

2nd Highest Price: Sievers Benchwork

Sievers has been around for a while, and their Model Railroad Benchwork products are composed entirely of 1×4 select pine lumber, also drilled for wiring runs. While the pine does offer good strength, we feel the size is a bit overkill for smaller width benchwork, and the use of dimensional lumber side rails increases the possibility of uneven benchwork surfaces.

The choice of material also drives their prices higher as a result. Their maximum 48” lengths necessitates the use of more leg assemblies for proper layout support, and the flat H-style legs don’t have the added strength or benefits of a braced L-Girder style leg such as offered by The Model Railroad Benchwork Store.

Leg leveling is achieved with the use of T-nuts that the customer must must install themselves. The absence of any positive layout assembly aid (layout marks only) can result in slight difficulty assembling the cross pieces square to the side rails for those with less carpentry experience.

As with the next two manufacturers, only pre-defined benchwork lengths and widths are available, and customization is an extra charge. Connections of the cross pieces to the side rails are identical to The Model Railroad Benchwork Store, with both manufacturers utilizing wood screws through pre-drilled holes for a simple but effective butt joint connection that has more than enough strength for a Model Railroad Benchwork frame.

Other options include 30 or 45 degree angle sections and riser blocks in 7-1/2, 9-1/2, 11-1/2, or 13-1/2 inch lengths.

3rd Highest price: MRBenchwork.com

Utilizing all ¾” plywood components, MRBenchwork.com (MRB for short) is the only manufacturer that doesn’t utilize any dimensional lumber in their products. While this may seem like a bonus at first, the use of all plywood does not come without disadvantages.

First and foremost is the ability to hold screws in the cross section of the plywood. This can be highly problematic when attaching plywood to the top, as the screws can easily strip in the plies, or even cause splitting. Once the plies have separated, any adjacent screws that are installed to facilitate fastening of a plywood top will only exasperate the problem.

And since your typical ½” or thicker plywood is rarely flat, the ability for the screws to hold well is essential for a reasonably flat surface.

Joinery of the cross pieces to the side rails is done with the use of pocket screws. While this method does produce a strong joint, the inherent movement of the piece being connected requires the use of clamps (long bar clamps) to keep the two parts tight. Over-driving the screws in an attempt to pull the joint together can also render the plywood cross joists useless.

It can also be difficult to achieve square joints without the use of a backing block since the screws have a tendency to twist the piece. This adds up to more effort to achieve satisfactory results as opposed to the end joinery method used by The Model Railroad Benchwork Store and Sievers.

H-style legs are the standard offering, and their limitations have already been mentioned above. L-girder style legs are available, but at additional cost. Bracing is not included. Leg levelers are only available as an option at an additional cost, and they are not installed.

The maximum length of their pre-defined sizes are a bit better than Sievers or Mianne at 84”, but still fall short of the 96” offered by The Model Railroad Benchwork Store.

Another minor point is the fact that if the benchwork is ordered with wiring holes, everything is drilled; including the side rails which is a bit unsightly in our opinion.

Options include diagonal sections, inside or outside curved sections, and risers in 8, 10, or 12 inch lengths.

Highest price: Mianne Benchwork

Mianne Benchwork’s selling point is their patented modular wood and hardboard I-beam modular parts system that can be rearranged at any point in time. Unlike The Model Railroad Benchwork Store, Sievers Benchwork, or Model Railroad Benchwork.com, they only offer singular components in pre-defined lengths.

Using their parts, they claim that any size or configuration layout can be made. However, in reality you are still limited to their standard length offerings unless you are willing to pay extra for custom lenghts. Additionally, designing a layout in this manner requires some knowledge of carpentry and measuring and determining the correct parts can be overwhelming for some. Mianne solves this by offering design services, albeit at extra cost.

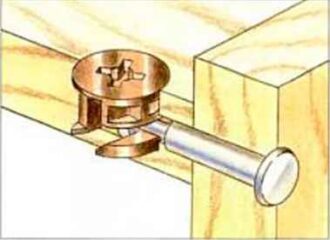

Their pieces assemble together using furniture style cam bolts, and while this does offer ease of use, cam bolts can loosen over time and the entire assembly could become wobbly. Use of flat H-style legs don’t offer much in way of lateral movement control unless assemblies are positioned at right angles to each other, and their placement along the side or end rail edges pose a kick hazard.

Like Sievers, their maximum available lengths are only 48”, requiring substantially more legs to support the benchwork as compared to The Model Railroad Benchwork Store. Leg levelers are available, but no information on type or adjustability could be found on their website. It is unclear if wiring hole passageways are provided.

The modular component parts system just seems a bit exotic and out of the price range for your typical Model Railroader, and the ability to ‘change’ your layouts configuration in the future just seems like it would take a lot of effort, negating the selling point of their benchwork.

Options include 45 degree I-beam pieces in pre-set lengths.

Top Pick: The Model Railroad Benchwork Store

In terms of design and value, The Model Railroad Benchwork Store’s kits stand out with their 96” one-piece side rail construction and staggered joint method for longer tables that eliminate additional costly leg assemblies.

Their pressure block assembly system offers a unique and positive approach to alignment, unlike Sievers or MRB which offer no positive means of keeping everything aligned and square. And although Mianne does have a positive positioning method, the use of cam bolts has their own shortcomings as already mentioned.

Out of all four manufacturers, only The Model Railroad Benchwork Store offers pre-assembled L-girder style legs with leveling inserts already installed as their standard offering; a huge advantage in our opinion, especially when you’re looking for a hassle free benchwork kit. This alone makes them stand out from the competition.

The choice of materials by The Model Railroad Benchwork Store also combines strength in critical areas, and value elsewhere instead of needlessly upsizing materials or using more exotic joinery; just tried and true methods that are more than adequate for a Model Railroad frame foundation. When you combine all of these standard features, ease of assembly, and endless size options, it’s clear that The Model Railroad Benchwork Store is a top choice for those looking for an affordable, well thought out and strong benchwork solution.

About the Author

James, the founder, and owner of The Model Railroad Benchwork Store, has been a Model Railroader for over 45 years and has built many different layouts during that time. He is also a carpenter by trade for nearly 40 years, which includes 7 years in cabinet making.

Using his extensive knowledge of woodworking and real world applications of engineering loads and principles, he designed his products to exceed all expectations for a Model Railroad Benchwork setup. Affordability and ease of assembly were also important factors in the design phases.

The result is an affordable Model Railroad Benchwork product line with features and upgrades that are only available by paying extra elsewhere.

Copyright 2025 The Model Railroad Benchwork Store/Model Railway Techniques.com All Rights Reserved

Last Updated on 1 year ago ago by James from Model Railway Techniques